Products

-

Industrial wastewater treatment

-

Fiberglass Cooling Tower Series

-

Industrial combined concrete structure countercurrent square hollow tower

-

Industrial combined steel structure countercurrent square hollow tower

-

Industrial combined concrete structure cross-flow square tower

-

Industrial combined concrete structure countercurrent turbid water square tower

-

Industrial combined concrete structure counter-flow square tower

-

Standard combined steel structure countercurrent square tower

-

Industrial combination steel structure countercurrent turbid water square tower

-

Industrial combined steel structure countercurrent square tower

-

XFS Advanced Oxidation and Electrolysis Technology

- Commodity name: XFS Advanced Oxidation and Electrolysis Technology

- Description

-

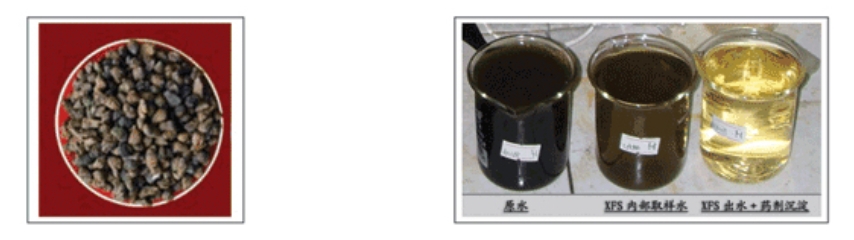

C、 XFS advanced oxidation technology

XFS advanced oxidation technology is to decompose phenol, ammonia and cyanogen compounds in wastewater by forced oxidation using catalytic carriers under special circumstances, with special precipitation agents. Technology of removing complex precipitate from water. XFS advanced oxidation, as a pretreatment technology independently improved and innovated by Hongliu Company with reference to foreign technology, is especially suitable for the treatment of high-concentration complex organic compound wastewater such as coking and chemical industry.

XFS advanced oxidation equipment features:

1. According to the reaction flow pattern and turbulence probability, a gas-water-solid three-phase reactor is carefully designed, so that the wastewater and the carrier are fully mixed in the reaction zone and well separated in the release zone.

2. Working at normal temperature and pressure, the operation is simple, the management is convenient and the running cost is low.

3. Different catalysts and oxidation fillers are used for different types of wastewater.

4. The filler has long service life; The utilization efficiency of oxidant is high.

5. It has obvious treatment advantages for high concentration, refractory and toxic wastewater from coking, chemical and pharmaceutical industries.

↓A3 filler is suitable for pretreatment of coking wastewater.

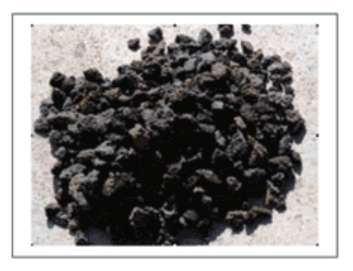

D、 Micro-electrolysis technology

Micro-electrolysis technology is a micro-electrolysis process formed by corrosion of iron-carbon granules in electrolyte solution. An electrochemical technology to treat wastewater. The electrode reaction process does not consume electricity, but can produce redox, Electroagglomeration, etc.: The new ecological Fe2+ produced by electrode reaction is a coagulant with strong adsorption, containment and complexing ability. Therefore, the micro-electrolysis method is characterized by multiple action mechanisms, strong synergy, good treatment effect on organic matter, and improved biodegradability of wastewater. With the subsequent biochemical treatment, the operating cost is also low. Iron-carbon granular material is the core material of micro-electrolysis equipment, and its performance is directly related to the effect of wastewater treatment.

Related Products

Welcome your message consultation

Our staff will contact you within 24 hours (working days). If you need other services, please call the service hotline: +86-510-87877888